Their careers at the University of Saskatchewan began five decades apart, but the research into concrete by chemist Thorbergur Thorvaldson and engineer Karim Nasser—both immigrants to Canada—has contributed to making large structures in Canada and around the world more durable, safer and more economical.

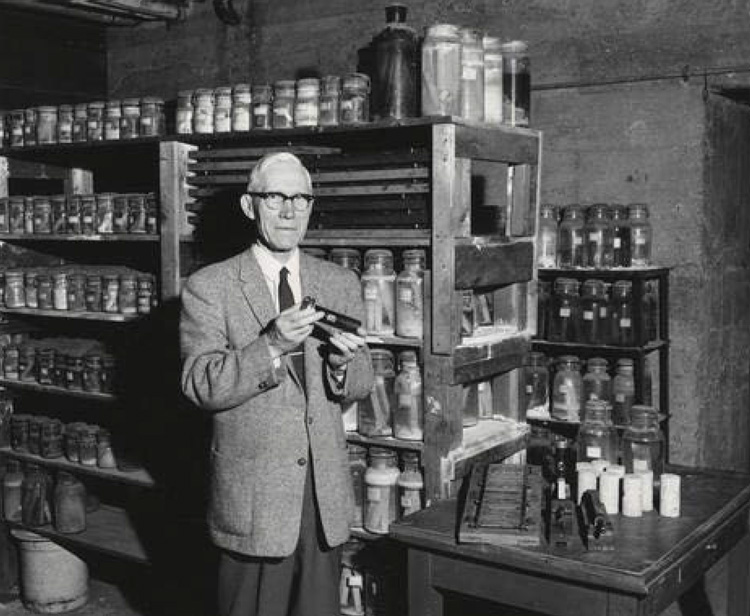

Born in Iceland, Thorvaldson immigrated to Manitoba with his parents in 1887. After studying in Europe and at Harvard, he joined the U of S chemistry department in 1914 as an assistant professor, and became department head in 1919. At the time, the deterioration of concrete structures—from Winnipeg’s sewers to public buildings in Saskatoon—was becoming a concern and drew the attention of C.J. (Chalmers Jack) Mackenzie, dean of the U of S College of Engineering.

Thorvaldson began working with Mackenzie on an interdisciplinary approach to the problem. The research determined that sodium and magnesium sulphates found in the ground in many areas of Saskatchewan were primarily responsible for damage to sub-soil portions of the structures. Groundwater containing sulphates was penetrating the concrete, reacting with tricalcium aluminate (C3A) in the cement. The northern Great Plains states, the Canadian Prairies and sites in southern Ontario shared the problem, which was rare elsewhere.

Thorvaldson and his graduate students spent the next decade researching ways to prevent the deterioration, and their solution—sulfate-resistant concrete—has stood the test of time.

“By 1926 the group at Saskatchewan had shown that variations in the chemical composition of Portland cement (the basic ingredient of concrete)… had a large effect on the sulphate resistance of the cement,” Thorvaldson wrote in a March 1949 letter that emphasized the university’s key role in the invention.

The letter was a rebuttal of a report that had credited the chief chemist from the Canada Cement Company (who had filed for a patent) for developing a sulphate-resisting cement. Thorvaldson noted that his researchers identified C3A as the compound responsible for the most acute failures of Portland cement concrete, especially in groundwater that contained sodium sulphate.

From examining several commercial cements and from his team’s studies on C3A, Thorvaldson had concluded that the sulphate-resistance of Portland cement could be materially increased by substituting an iron compound for part of the alumina in the mix. His team, in fact, worked closely with Canada Cement on a steam treatment process to produce a sulphate-resistant low-C3A variety that became known as Type V Portland cement and is now known as Type HS.

Thorvaldson’s development of a formula for sulphate‑resistant cement made concrete durable in alkali soils for the first time and led to a world-wide change in the manufacture of commercial concrete.

In 1966, eight months after Thorvaldson’s death, the Chemistry Building was renamed the Thorvaldson Building in his honor, as was Thorvaldson Lake in northern Saskatchewan.

If Thorvaldson laid the foundation for the university’s reputation for fundamental research on concrete, the research and innovative industrial applications developed by Karim Nasser during a 33-year academic career at the U of S elevated the profile sky high. Born and raised in Lebanon, Nasser studied in Beirut, Kansas and the U of S, before joining the U of S as a professor of civil engineering in 1961.

The best known among his inventions is the K-Slump Tester, first used in the construction of the CN Tower in 1973 to measure consistency—the ability of a freshly mixed batch of concrete to flow. Another is a five-hour strength tester that has reduced to a fraction of time the 28 days it usually takes to cure and test a batch of concrete to determine its compressive strength.

Among Nasser’s other inventions are a pin penetration tester that’s a non-destructive apparatus for in situ testing of hardened concrete, and a mini air meter that indicates the air content of freshly poured concrete.

Nasser’s research covered many facets, from the creep of concrete—compression or stress behaviour in structures over the long term by strains placed on them—to the study of concrete containing Saskatchewan fly ash and other mineral byproducts used in such things as nuclear reactors, bridges dams, hydraulic structures, and towers.

Like Thorvaldson, who felt that “no individual should benefit financially from the results of research supported by the public purse,” Nasser gave to the U of S the royalties he received from the sale of his inventions.

“I was an employee of the university and anything I made outside of the university I had to share,” he told students attending the C.J. Mackenzie Gala of Engineering Excellence that honoured him as Distinguished Lecturer in January of 2017. “You have all the facilities, all the supports, so you have to pay back, look after the university.”

Concrete advice from a man whose family has been a generous supporter of the U of S for more than 50 years.

Sarath Peiris is a communications contributor for U of S Research Profile and Impact.